Vacuum forming, thermoforming

Vacuum forming and thermoforming is a process for forming thermoplastics. Special aluminium moulds with vacuum holes or steam nozzles are frequently used in these processes. Porous metals are increasingly used for these purposes.

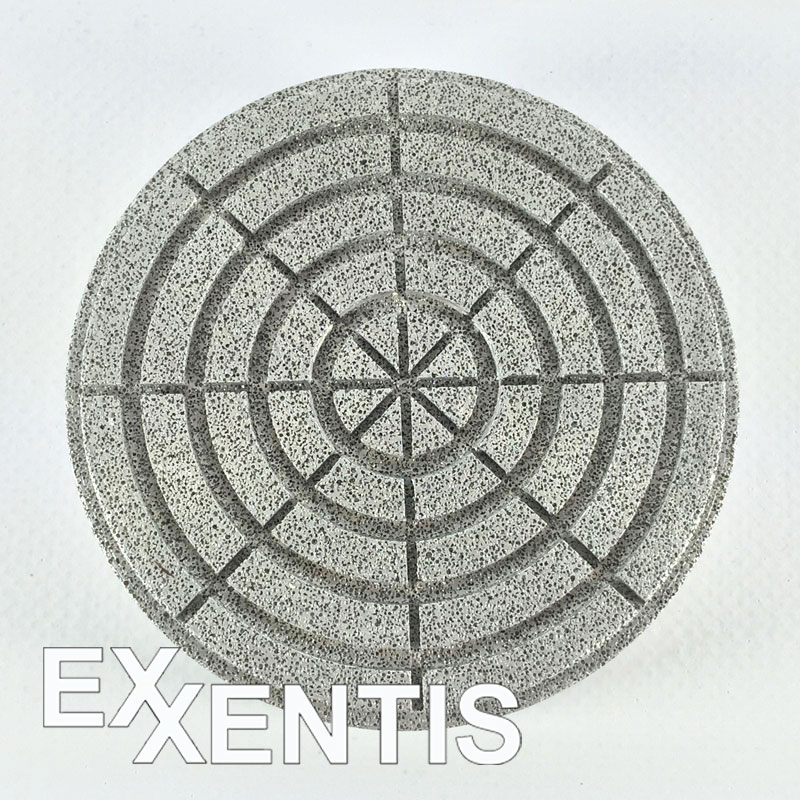

Porous aluminium is excellent for the production of foaming and thermoforming tools:

completely permeable, eliminates the need to drill vacuum holes or steam nozzles;

Aluminium is a highly heat conductive metal, ensuring rapid cooling of the tool;

high strength thanks to cast structure, thus long life of porous aluminium moulds.

Compared to conventional solid aluminium moulds:

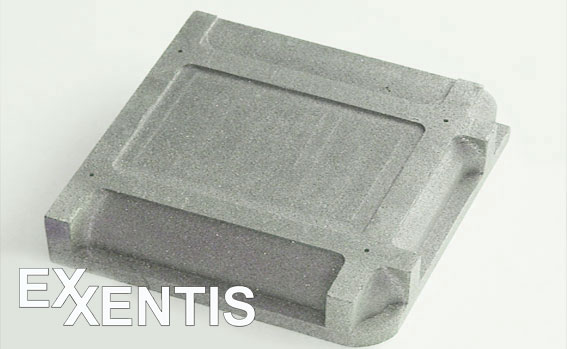

1. Complex shapes without vacuum holes or steam nozzles

In the production of moulds from solid aluminium, very complex shapes are often not feasible. The reason for this is the impossibility to create channels for vacuum or steam in such moulds; it can also be very difficult to supply vacuum or steam to such channels.

Thanks to uniform distribution of pores in porous aluminium and its permeability in all directions, it is possible to produce the most complex shapes without restrictions.

2. Uniform distribution of the vacuum / steam

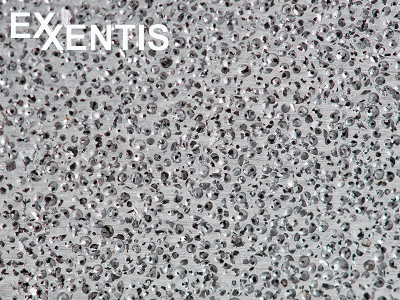

The surface of the porous aluminium consists of approx. 50% pores. This ensures an absolutely uniform supply of vacuum or steam at every point. This makes the homogeneity of the properties of the plastic product very high compared to the use of relatively rarely arranged channels for vacuum and steam.

3. Half of the weight (density 1,2-1,0 g/cm3)

The low weight of porous aluminium enables the production of lightweight moulds for foaming and thermoforming tools. The whole construction is greatly simplified and the weight is also reduced because there is no need for tubes/tubes to supply the vacuum or steam.

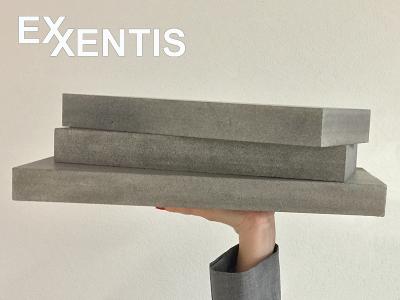

5. Fast prototype production from prefabricated blocks

You can machine porous aluminium under special machining conditions (high rotational speed, thin cut and sharp edge) on lathes, milling machines and other machines. This enables you to quickly produce complex moulds for the production of prototypes or series production.

6. Working temperature up to 250...550 °C

Porous aluminium is a cast material, it contains no composite materials such as glue or resin and can also be used at high temperatures.

Porous aluminium has a unique combination of material properties:

- all products are permeable over the entire volume

- can be produced up to large formats and in any shape

- high strength thanks to cast structure

- high and controllable volume porosity

- different and controllable pore sizes

- homogeneous distribution of the pores over the entire volume